ABOUT US

Welcome to the company Ruhrzerspanung!

We are a family-run company specializing in the production of machine components on CNC-controlled lathes, milling machines and grinding machines and are certified according to the standards DIN EN ISO 9001:2015 and DIN EN ISO 14001:2015. Our possibilities in the job order production are precise, flexible and versatile.

Precision

Based on technical drawings, machine components are produced in a three-shift operation. With our machines and over 30 employees we are able to meet highest quality requirements. Our range of customers includes the gear manufacturing industry, hydraulic, recycling and the construction machinery industry as well as the general mechanical engineering.

Flexibility

The production consists of individual parts as well as small and medium-sized batch sizes. Our 19 machines cover a wide variety of machining possibilities. We work with materials either provided by you or offered by us. Competent partners are available for those work-flow procedures which are not covered by us, enabling us to produce complete components and modules.

Versatility

Our goal is to completely satisfy you in terms of management, technical advice, flexibility, quality and the adherence to delivery dates. With over 25 years experience in this business, we successfully follow these values. The close communication with our customers is important to us which is why we look forward to getting in touch with you too.

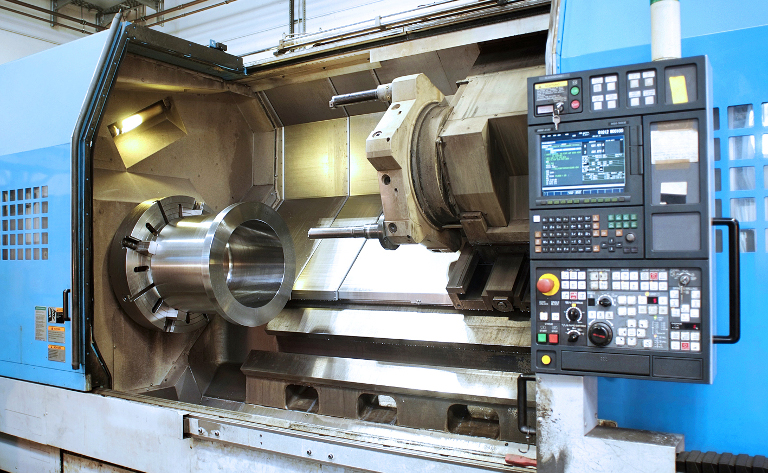

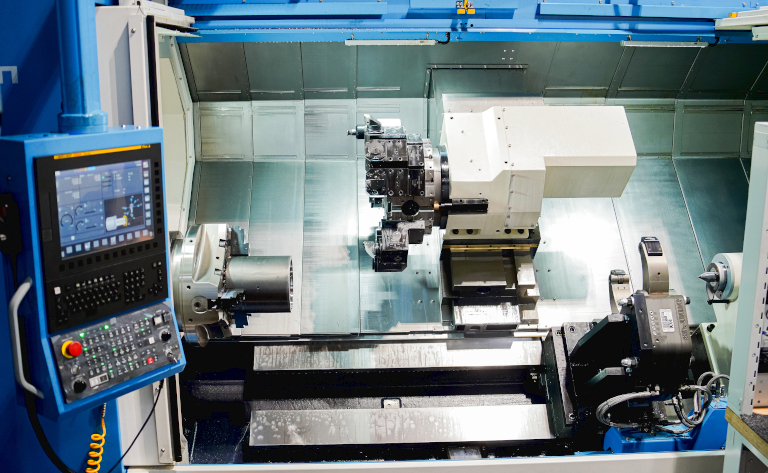

TURNING

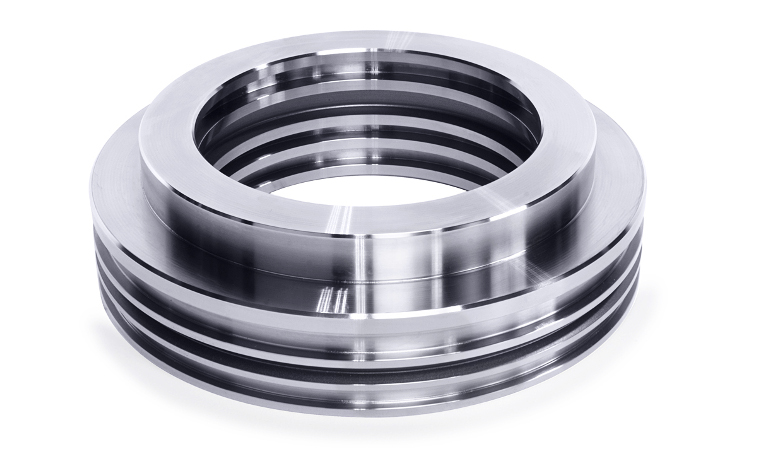

Highlights in the turning area at Ruhrzerspanung

We are able to machine components with a diameter of up to 970 mm and a length of up to 4,250 mm. These photos show you some selected lathes in our production as well as work pieces we have manufactured for our customers.

Not sure whether our machines cover your components? Contact us, we will be happy to assist and advise you.

MILLING

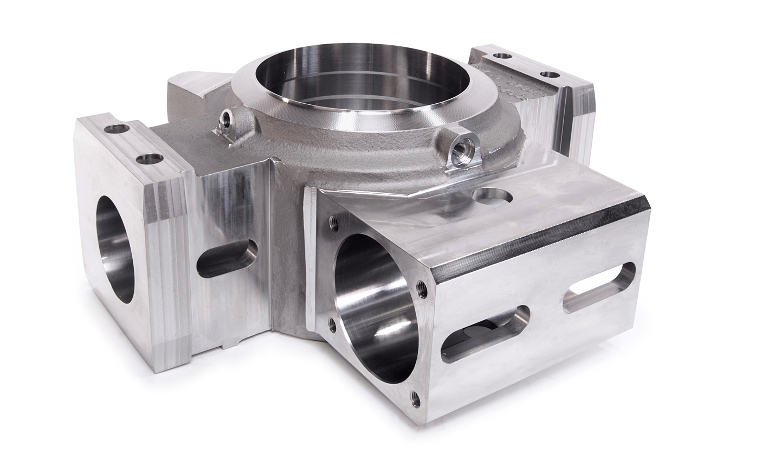

Highlights in the milling area at Ruhrzerspanung

In our gallery you will find some of the workpieces we have manufactured for our customers. You will also see selected milling machines in our production and our mobile coordinate measuring system, the Keyence XM-5000, which supports our quality assurance for both small and large components. We are able to machine components with a length of up to 5,000 mm, a width of up to 1,000 mm and a height of up to 1,300 mm.

Not sure if we are the right partner for the production of your components? Feel free to contact us, we will be happy to assist and advise you.

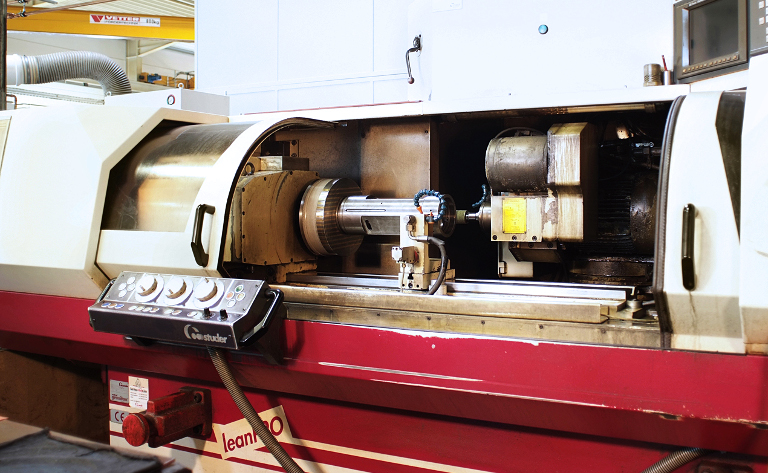

GRIDNING

Highlights in the grinding area at Ruhrzerspanung

With our grinding facilities we are able to machine parts with a diameter of up to 340 mm and a length of up to 1,000 mm.

Do your components require both challenging tolerances and surface quality? Are you looking for an experienced partner? Contact us, we will be happy to assist and advise you.